Scan the QR code or use the link https://animations.cloudproduct.info/bracket/ for a step by step fixings installation animation with tool (D). If you have a 'Torque Wrench' then that can be used instead of tool (D) and skip the animation and proceed from step 12.

- (Step 1 of the animation) Hand tighten LH fixing. See step 12 in these instructions for further information if required.

- (Step 2 of the animation) Hand tighten RH fixing. See step 13 in these instructions for further information if required.

- (Step 3 of the animation) For LH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to tighten 90° (align 90° with bumper to aid in getting the correct angle). Then untighten fixing 90° before proceeding to the next step.

- (Step 4 of the animation) For RH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to tighten 90° (align 90° with bumper to aid in getting the correct angle). Then untighten fixing 90° before proceeding to the next step.

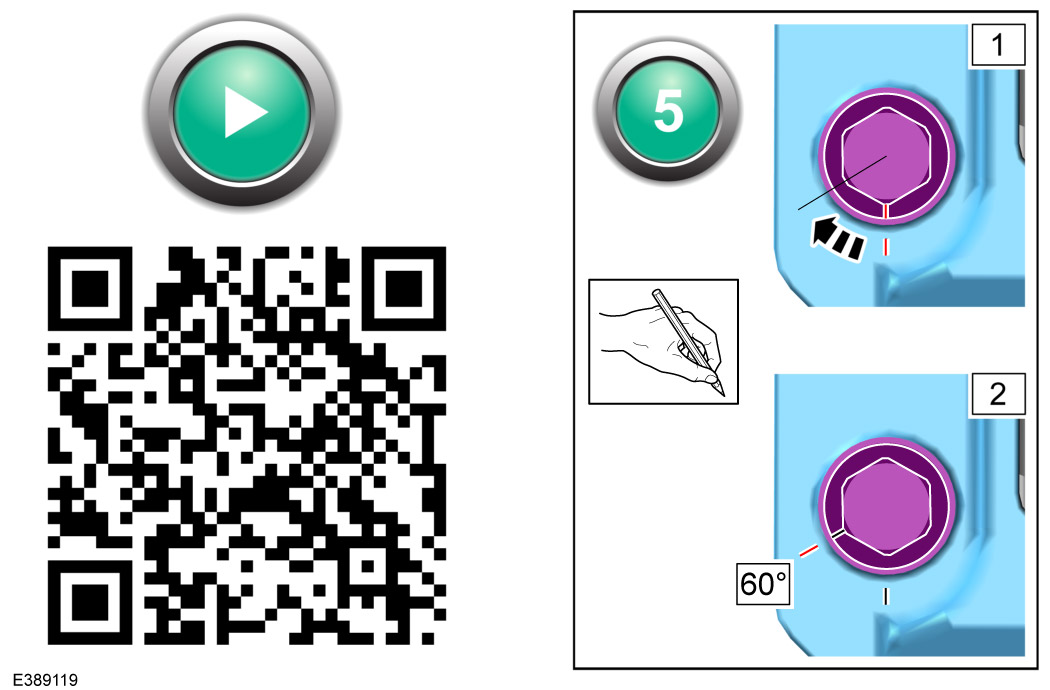

- (Step 5 of the animation) For LH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to tighten 60° (each face on the fixing is 60°. The graphic above will aid you in marking up the correct start and finish position of fixing. Then untighten 60° before proceeding to the next step.

- (Step 6 of the animation) For RH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to tighten 60° (each face on the fixing is 60°. The graphic above will aid you in marking up the correct start and finish position of fixing. Then untighten 60° before proceeding to the next step.

- (Step 7 of the animation) For LH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to do a final tighten of 60° (use the markings made in the previous steps to aid you in the correct torque).

- (Step 8 of the animation) For RH fixing. Place only the thumb and index finger onto the end of tool (D) (not in the tool hole) and pinch tightly. Then place tool (D) onto the fixing and begin to tighten until fingers slip of the tool naturally. Then use tool (D) to do a final tighten of 60° (use the markings made in the previous steps to aid you in the correct torque).

- Installation complete. The remaining steps are only for installation with a 'Torque Wrench' only.