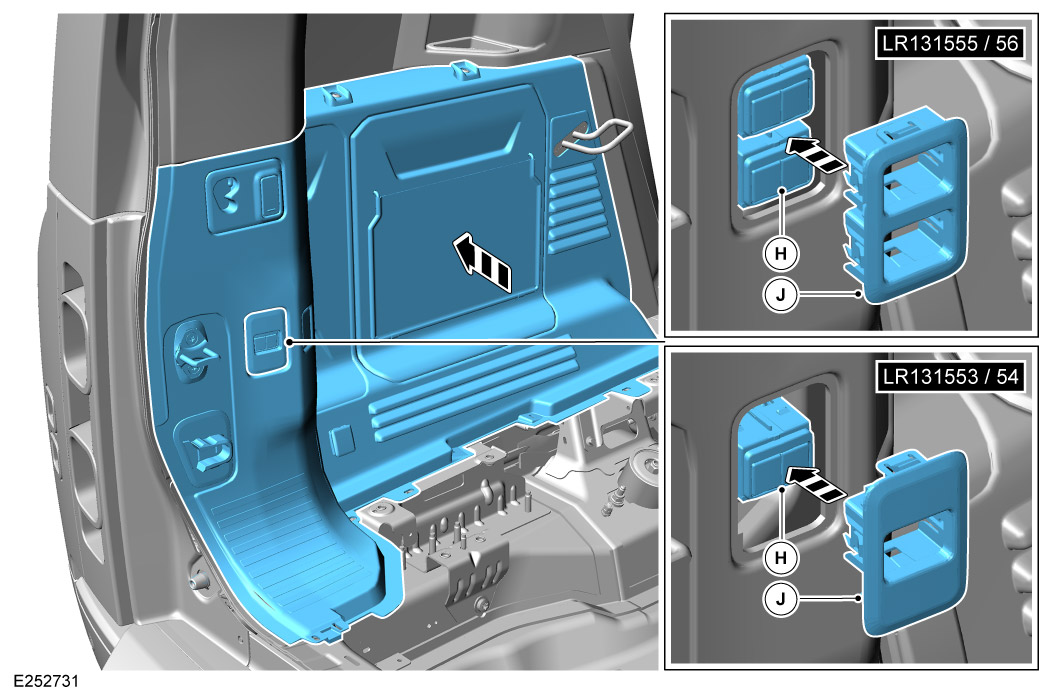

Offer up the 'Left Loadspace Trim Panel' back to the original position. Then install the switch panel (J) to the electrically deployable towbar switch (H), then install the switch panel (J) to the loadspace left trim panel.

- After the switch is installed, then install the 'Left Loadspace Trim Panel' back the vehicle.

- For additional information, please refer to the official Workshop Manual. Rear Quarter Trim Panel - 90 (501-05 Interior Trim and Ornamentation)

- For additional information, please refer to the official Workshop Manual. Left Loadspace Trim Panel - 90 (501-05 Interior Trim and Ornamentation)

- For additional information, please refer to the official Workshop Manual. Left Loadspace Trim Panel - Vehicles With: Commercial Specification (501-05 Interior Trim and Ornamentation)