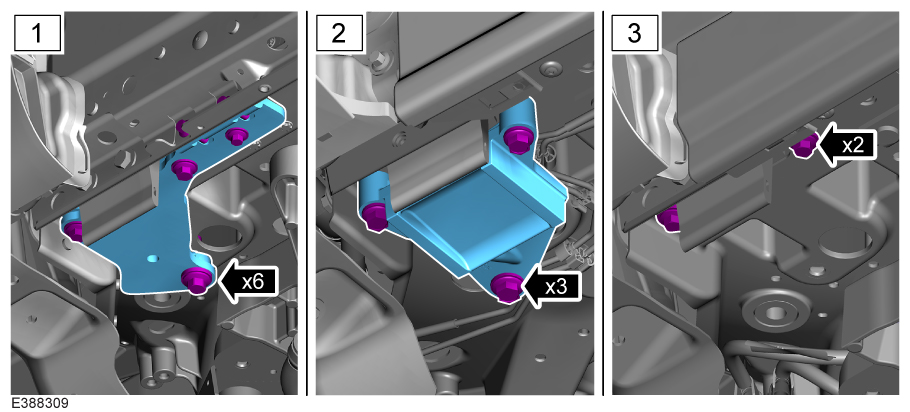

Depending on vehicle variant, you may be required to remove any fixings or front mounting brackets in the area under the removed jacking point cover.

- Variant 1 = Remove x6 fixings and mounting bracket.

- Variant 2 = Remove x3 fixings and mounting bracket.

- Variant 3 = Remove x2 fixings.