Install the front fender moulding panel, with the front mud flap attached, to the vehicle.

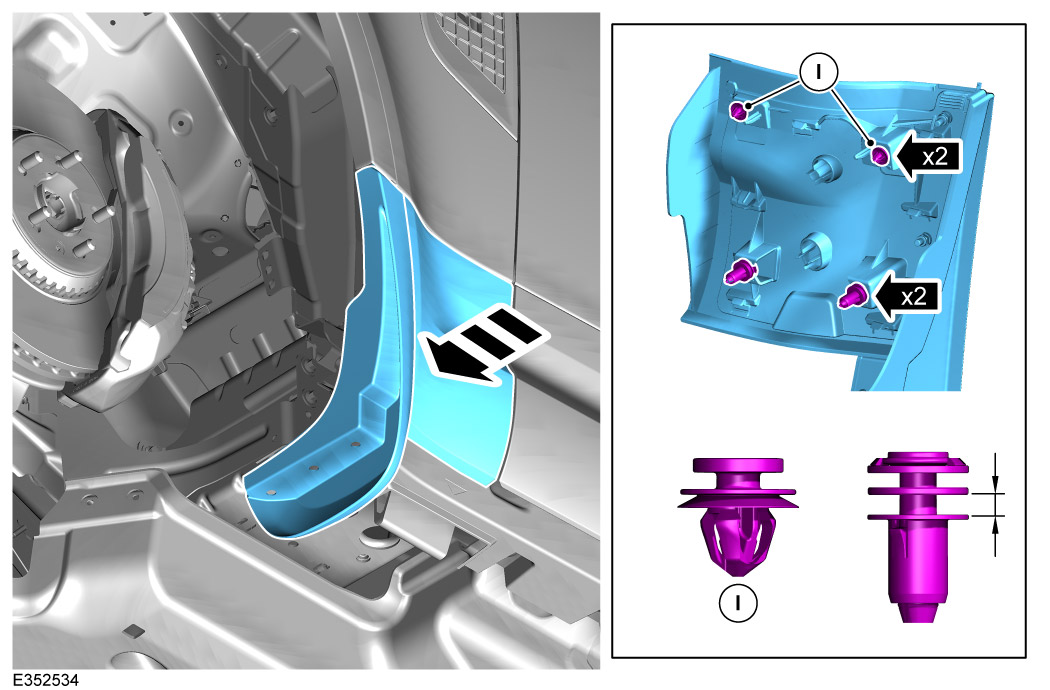

- Adjust the x2 bottom clips to the correct gap as illustrated before installation.

- Install x2 upper clips (I).

- Offer up the front fender moulding panel with mud flap to the vehicle and carefully push the front fender moulding panel into the vehicle engaging the x4 clips.

- The fender moulding panel must be correctly aligned to the surrounding bodywork.